Franklin Court, London, Renovation

- Location

Franklin Court, London - Duration

83 Days - Contract Value

£220 000

Client Feedback

“The owners of all apartments in this residential high-rise building decided to renovate their several rooms.”

Full Apartment & Communal Renovation — Franklin Court, London

Project Overview

British Builders was appointed by Archers to deliver a full refurbishment at Franklin Court, a residential high-rise in central London. The works combined essential structural repairs with a complete upgrade of communal areas and private apartments in an occupied building.

Scope of Work

- Roof remediation including new insulated outlets, damp-proofing layers and PIR insulation to Bauder specification

- Replacement and upgrade of storm drains, guttering and downpipes

- Full electrical rewire to communal areas, including new LED and emergency lighting

- Installation of new fire and smoke alarm systems and compliance signage

- Redecoration of landings, staircases and corridors with durable wall finishes

- Installation of heavy-duty vinyl flooring to communal circulation areas

- Full refurbishment of individual apartments with new fitted kitchens and contemporary bathrooms

- Installation of engineered wood flooring and full internal redecoration to each flat

Challenges & Solutions

- Hidden roof defects and drainage failures – Incorporated additional storm drain and waterproofing works into the programme, using Bauder-approved details to ensure long-term performance without major delays.

- Complex multi-phase works in an occupied building – Implemented a phased schedule allowing roof, communal and apartment works to run in parallel, while maintaining safe access and minimising disruption to residents.

- Tight budget and fixed completion date – Used rotating specialist teams and just-in-time material deliveries to keep productivity high, control costs and protect the client’s budget.

Final Outcome

The project was completed under budget and two weeks ahead of programme, delivering a watertight, energy-efficient roof and modern, robust communal areas. Individual apartments were fully upgraded to a high specification, providing residents with refreshed, comfortable homes and significantly improving the overall value and appearance of the building.

Client Feedback

“British Builders delivered a complex, multi-phase refurbishment at Franklin Court on time, under budget and to an excellent standard. Both the communal areas and the apartments have been transformed, and disruption to residents was kept to a minimum.” – Archers

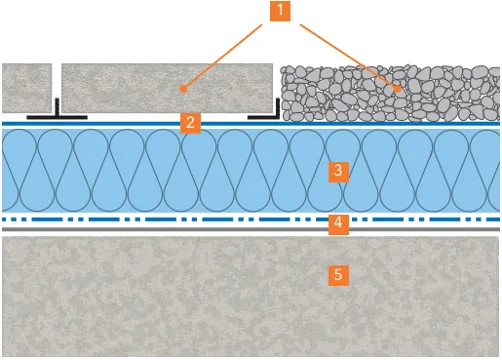

- Surfacing / Ballast (e.g. paving or pebbles)

- Water Flow Reducing Layer

- Inverted Roof Insulation Boards (e.g. extruded or expanded polystyrene)

- Waterproofing System

- Structural Deck (e.g. concrete)